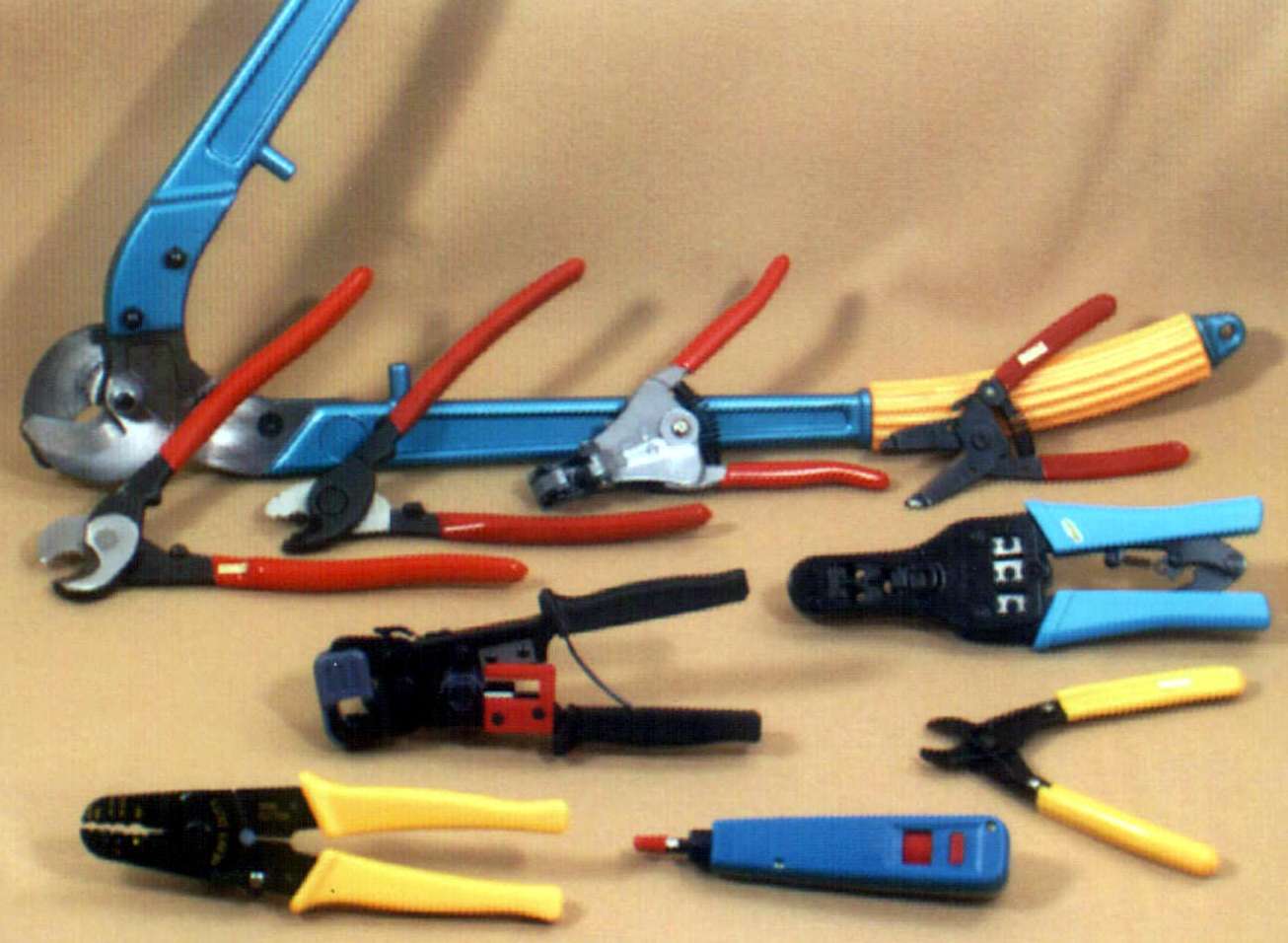

We ballpark around $3/square foot to pigtail whole house, but we will need to get a count of everything and see what type of new outlets and switches you would like installed. They are the most cost effective solution to remedy aluminum wiring. We prefer to use purple wire nuts because they are simple to install, take up less space in the already small boxes, and don’t require any specialized training from manufacturers. The methods in which they are installed is what determines how effective they are. We have used all three, and each one is a perfectly viable solution to the problem. You can find pros and cons to each method depending upon what website you look at and who is sponsoring that page. They have a higher heat rating than regular wire nuts and have an antioxidant built in to prevent the copper and aluminum from oxidizing when mixed together. You have to be certified by their manufacturer with a class and the costs for the tools and materials are higher than the other methods. Copalum is a cold welding crimp that uses special crimps, a crimper, and heat shrinks to seal the connection. It is rather large and harder to work with. Alumiconn is a type of terminal block that terminates each wire separately. There are a few different types of connectors available: Alumiconn, Copalum, and purple wire nuts. This joint is then pushed to the back of the box, and the copper wires are now attached to your outlets, switches, and light fixtures. A UL listed connector must be installed for this application for it to be a legal install. This option is taking the connections at your outlets, switches, and light fixtures and joining in a copper conductor with the aluminum ones. The last option is pigtailing the aluminum wires. Pigtailing Using Alumiconn, Copalum, and Purple Wire Nuts Co/ALr rated devices are no longer a viable solution to remedy aluminum wiring.

ALUMINUM TO COPPER WIRE NUTS INSTALL

There are no Co/ALr rated GFCI’s that we are aware of so we can’t install them where needed. The same holds true for GFCI receptacles. All outlet replacements are required to be tamper-resistant. There also aren’t any tamper resistant Co/ALr rated outlets that we are aware of. This method is not a permanent install due to the additional work required every year. It is recommended that you go through all of your connections once per year and tighten them again.

ALUMINUM TO COPPER WIRE NUTS FREE

This connection is supposed to squeeze everything a little better, but at the end of the day, you’ve still got aluminum exposed to free air and with use, will work itself free. The screws that terminate the wires are a little larger to help press down on more of the conductor. They are devices that are rated for copper and aluminum connections. We typically won’t take on a whole house rewire project, but for numbers’ sake, we ballpark around $10 per square foot to rewire a house.Ĭo/ALr rated outlets and switches are another option that we get requests for from time to time. Not only is this the most expensive way to remedy the situation, but it will also cause other issues like a bunch of sheetrock repair. We get a lot of requests to rewire the whole house when aluminum wiring exists. There are a number of ways to remedy aluminum wiring.

If a remodel happened during the Vietnam era, you might have a portion of the house wired in aluminum. If it were built in the mid-70’s or later, you wouldn't have aluminum wiring either. The copper was being rationed for bullets. So if your house was built in the 50’s or before, you aren’t going to have aluminum wiring in it. These loose connections can lead to small problems like simple outages all the way up to larger problems like fires.Īluminum wiring on small branch circuits was only installed during the Vietnam War. As your electrical system sees more use over time, the aluminum connection points will work themselves free from the outlets, switches, and light fixtures they are connected to and cause loose connections. Aluminum will expand and contract more than copper will with use. They happen at the connection points of your outlets, switches, and lights. Even then, the problems don’t occur in the walls. The issues with aluminum wiring stemmed from their use in smaller branch circuit wires like the ones that feed your outlets, switches, and light fixtures. Large feeder wires for 240-volt items are typically run in aluminum as well to help save costs. Copper is too heavy to run overhead and too expensive to use in the mass quantities that they use for wire. All of the power company’s lines are aluminum. Aluminum wiring is still used today in many applications.

0 kommentar(er)

0 kommentar(er)